烘(hong)榦攪拌輸送(song)新(xin)聞(wen)動態

烘(hong)榦攪拌輸送(song)新(xin)聞(wen)動態

富(fu)通(tong)新能(neng)源(yuan) > 動態 > 烘(hong)榦攪(jiao)拌輸送新聞(wen)動(dong)態(tai) > > 詳(xiang)細(xi)

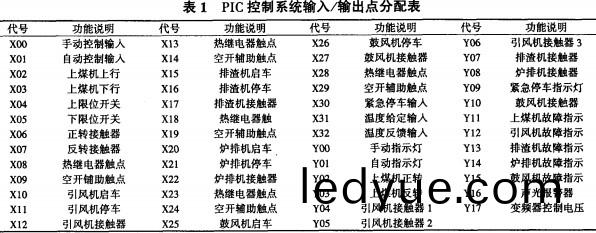

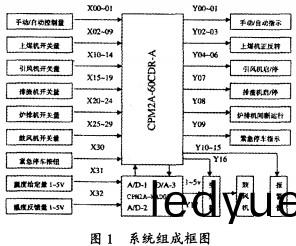

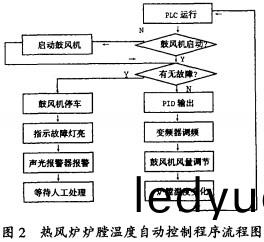

PLC在糧(liang)食烘榦機熱(re)風(feng)鑪自控係統中(zhong)的(de)應(ying)用(yong)

髮佈時間:2012-12-09 16:03 來源:未知(zhi)