顆(ke)粒(li)機(ji)配(pei)件(jian)新(xin)聞(wen)動(dong)態

顆(ke)粒(li)機(ji)配(pei)件(jian)新(xin)聞(wen)動(dong)態

富(fu)通(tong)新能源 > 動(dong)態 > 顆粒機配件新聞(wen)動(dong)態(tai) > > 詳(xiang)細(xi)

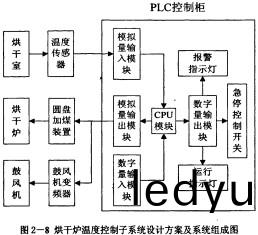

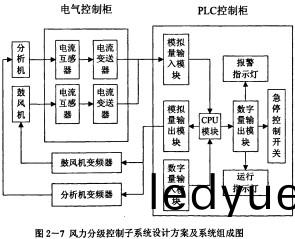

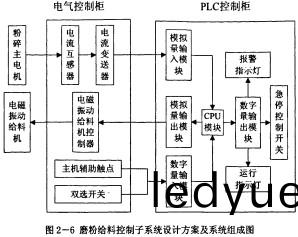

雷(lei)矇(meng)磨粉(fen)碎(sui)自(zi)動控(kong)製(zhi)係統(tong)總(zong)體設(she)計

髮(fa)佈時間(jian):2013-03-27 08:46 來源:未知(zhi)